LEARNING CENTER

COCONUT FATTY ACID DISTILLATES (CFAD)

WHAT ARE COCONUT FATTY ACID DISTILLATES?

Coconut Fatty Acid Distillates (CFAD) are the by-product of the physical refining of coconut oil. CFAD is used as a raw material for the manufacture of various products in several industries and will later be mixed with other ingredients to become a finished product that can be used for manufacturing such as soap, cosmetics, and food products.

HOW ARE CFADs MADE?

Coconut fatty acids are types of fatty acids derived from coconut oil using hydrolysis and distillation processes. CFAD 12-18 is recovered during the second stage in the distillation process after the hydrolysis stage. During the hydrolysis stage, RBD oil is mixed with water at high temperature and pressure conditions initiating the splitting process. The splitting process enables the formation of fatty acids and glycerol from triglycerides. The final product is a Long-Chain Fatty Acid Distillate consisting of C12 (Lauric Acid), C14 (Myristic Acid), C16 (Palmitic Acid) and C18 (Stearic Acid).

WHAT ARE THE DIFFERENT TYPES OF CFADs?

Dark amber-colored CFADs are typically made using crude coconut oil as the raw material or they can be a by-product of oil refining from other vegetable oils like palm, corn, canola, soya, olive, etc. Darker-colored CFADs usually contain contaminants and impurities that need to undergo further refining.

Our lighter-colored CFAD uses RBD (Refined/Bleached/Deodorized) Coconut Oil as the raw material and employs a fractionation process so the impurities and contaminants are already removed. Does not require further refining*. Further refining is possible as per client requirements.

APPLICATIONS AND USES

Some of the applications of Coconut Fatty Acid Distillate (CFAD) are as follows:

Soap making

Detergent / Laundry soap

Cosmetics

Lotions

Methyl ester

Biodiesel

Fatty alcohol

Anti-caking agent

It can also be used as an admixture for animal feed

Primarily CFADs are used as nonionic surfactants in various formulations both, industrial & cosmetic. These are also used as cleaning agents, wetting agents, dispersants or emulsifiers, softeners, and spin finishing agents in textile formulations.

It is often used as a raw material for soap making, detergent, shampoos, feed compounding, and oleochemical and biodiesel industries. Other common applications include rubber processing, candles, and cosmetic products or use as feedstock.

emulsifier

surfactant

degreaser

easy to dissolve in water

foam stabilizer

foaming agent

infiltration

It is a non-ionic surfactant, and it is especially obvious when the anionic surfactant is acidic. It can be compatible with a variety of surfactants and easily mix with other fatty acids.

INDUSTRIES WE SERVE

Coconut Fatty Acid Distillates (CFADs) is an extremely versatile product that can be compatible in many products that cover a broad scope of industries. The main industries we will cover are Chemical Industry, Personal Care & Cosmetics Industry, BIO-DEISEL, Leather & Textile Industry, and Animal Feed Manufacturers.

CHEMICAL INDUSTRY:

FUNCTION: Acts as a surfactant, cleansing agent, emulsifier, foam booster, foam stabilizer, foaming agent, and degreaser. Can enhance the cleaning effect in cleaning products.

The product can be widely used in the production and manufacture of water-soluble cleansing solutions, lubricating agents, parting compounds, soaps, detergent, shampoo, liquid detergent and can enhance the cleaning effect in cleaning products.

PERSONAL CARE & COSMETICS INDUSTRY:

FUNCTION: Used as an emulsifier and solubilizer in cosmetics & health care formulations.

There is a tremendous growing demand for bio-based eco-friendly products, particularly in the personal care & cosmetic industry. It not only boosts/stabilizes foam, and thickens liquid, but can also reduce irritation to the skin.

Assists in hydrating, minimizing wrinkles & fine lines, moisturizing, smoothening, and protecting skin from pollution and UV rays. Due to their high antioxidant, anti-inflammatory, anti-fungal, and anti-microbial properties, it is being used in body lotions, face creams, moisturizers, sunscreen, soaps, and others.

Acts as a cleansing agent, conditioner, emulsifier, and foam booster in soaps, baths, and hair care products and as an emulsifier for facial creams and lotions.

BIO-DEISEL INDUSTRY PART 1

Energy is a primary human need. This is an important key in economic sectors such as food, industry, transportation, agriculture, and power generation. Fuel and energy crisis and the concern of the society for the depleting world’s non-renewable energy resources led to a renewed interest in the quest for alternative fuels. Biodiesel is a liquid fuel similar to petroleum diesel (physical and chemical properties) in combustion properties, but essentially free of sulfur, making it a cleaner-burning fuel than petroleum diesel. Biodiesel is derived from renewable energy sources, such as vegetable oils and animal fats. However, biodiesel properties can sometimes be superior than that of petro-diesel fuel because the former has higher flash point, ultralow sulfur concentration, better lubricating efficiency, and better cetane number.

BIO-DEISEL PART 2

Both, non-saturated fatty acids contents of vegetable oils, such as: coconut oil, palm, soybean, rape-seed, woody oils and the like, can be converted into fuels. Coconut oil as other vegetable oils are com- pounds consist of various kinds of triglyceride fatty acids and about 90% are saturated fatty acid compounds. Coconut oil is rich in fatty acids (C8-C12), especially lauric acid and myristic acid. As a raw material it has advantages than other vegetable oils, it contains medium-chain fatty acids about 70% making it possible to obtain other fuels such as kerosene or jet fuel.

LEATHER & TEXTILE INDUSTRY:

Oils and fats are important additives in the fiber spinning and fabric manufacturing stages of textile fiber processing. While fatty acids from natural oils still play a role in textile processing, oxidatively stable synthetic oils have superseded their natural counterparts.

The textile industry is under pressure to reduce the amounts of or eliminate these additives, because of the environmental implications of the effluents. Recent developments to reduce the environmental impact of textile auxiliaries include the bio‐scouring process, which utilizes enzymes to catalyze hydrolysis of warp sizes and impurities in cotton; specialty surfactants developed to allow combining of desizing and scouring without the use of amylase; a biodegradable stabilizer incorporated into a hydrogen peroxide bleach bath to reduce the load on wastewater treatment facilities; and reformulated surfactants to replace alkyl phenol products that biodegrade to materials that are toxic to aquatic life.

CFAD is also developed for the lubrication of machineries of the textile and fibers manufacture industry. The main properties requested for textile oils are: colourless, anti-stain property to prevent deterioration of fibers and tissues in case of accidental contact and washability to allow its removal from the textile manufacture.

ANIMAL FEED MANUFACTURERS:

There has been much interest in the development of animal feed supplements designed to maintain immune function and growth in the absence of antibiotic feed additives.. Adding a feed or oil ingredient supplies the animal with essential fatty acids, needed for production and growth.

In recent years, replacing antibiotics in animal feedstuffs with biologically active substances has become a very current topic. The trend of banning the use of antibiotics, coccidiostats and other medical growth promoters in animal feedstuffs has developed because of fears these compounds contribute to the spread of bacterial resistance. Removing antibiotics from feedstuffs, after they were banned by the European Union (EU) in 2006, has put great pressure on livestock producers to find alternatives to antibiotics. Hence, modern feedstuff production is based on adding bioactive ingredients to feed, which should reduce the need for antibiotics and other medication, and positively influence animal health and welfare.

SOURCES:

https://www.mdpi.com/2076-2615/11/1/196/htm

https://www.allaboutfeed.net/animal-feed/feed-additives/animal-fat-nutritious-ingredient-for-animal-diets/

https://oilproducts.eni.com/en_GB/areas/lubricants/industrial-lubricants

https://iopscience.iop.org/article/10.1088/1755-1315/175/1/012025/pdf

https://www.sciencedirect.com/science/article/abs/pii/S0960148120316487

COCONUT vs. PALM MCT OIL

In the edible oil industry today, MCT Oil has been taking the market by storm offering noticeable health benefits and pushing limits in ways the product is used in mixtures with other essential oils. Cooking use, and recently in powder form. MCT stands for Medium Chain Triglycerides. These are healthy medium-chain fatty acids that are much faster digested and assimilated into your body compared to their long-chain counterpart mostly found in vegetable cooking oil. MCTs are commonly found in Palm and Coconut Oil. Both their DNA is comprised of over 50% MCTs. Coconut containing over 80% MCTs and Palm having an average of over 50% MCTs.

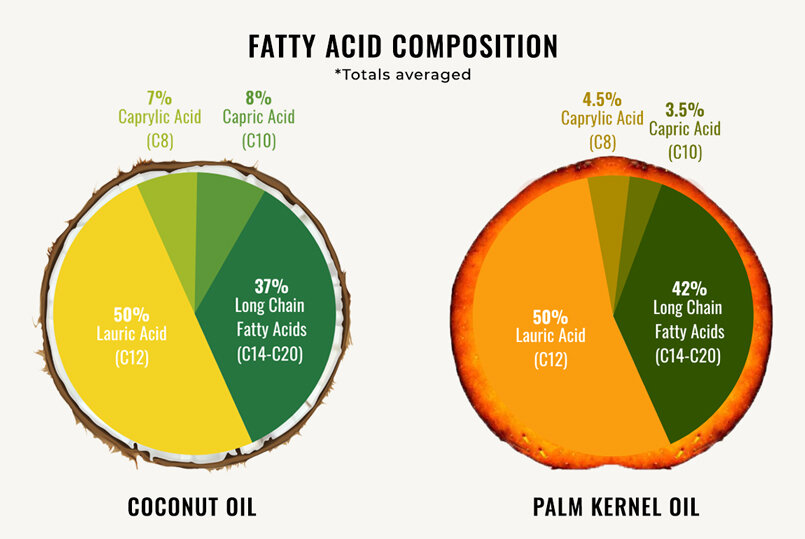

MCT Composition of Coconut Oil and Palm Kernel Oil

MCT oil is a byproduct of coconut or palm kernel oil that is produced by extracting pure MCTs from the whole fruit. Both Coconut and Palm oil-derived MCTs carry the top 3 medium-chain fatty acids (Lauric, Caprylic, and Capric) but the composition of fatty acids slightly differs for each. Coconut Oil, which is widely known for its skin and hair care benefits as well as its intake benefits, is comprised of over 50% C12 Lauric Acid and 12 – 15% of C8 and C10. The dominant fatty acids in palm kernel oil are lauric acid (48-50%), myristic acid (17%), oleic acid (18%), and has very small traces of caprylic and capric acid (7%). Typical MCT Oil is comprised of nearly 60% C8 Caprylic Acid, and nearly 40% Capric Acid with just about 2% C12 Lauric Acid.

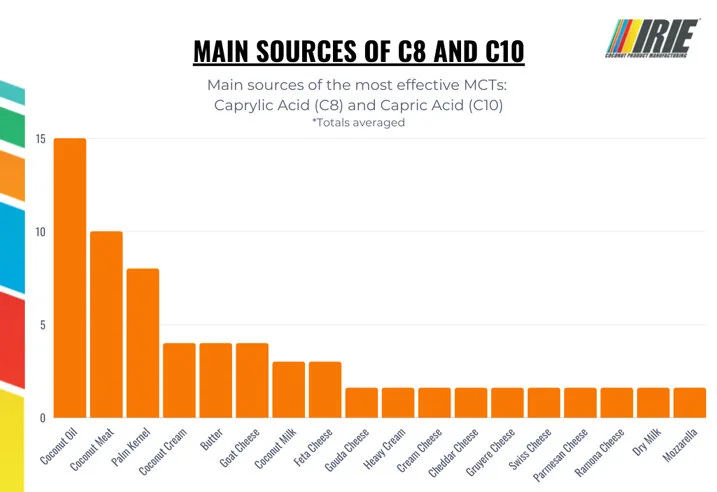

Richest Sources of C8 and C10

Caprylic (C8) and Capric (C10) acid are the most desirable MCTs due to their shorter chain length. And although Coconut Oil and Palm Kernel Oil are both rich food sources of MCTs coconut oil still has the highest percentage of Caprylic and Capric Acid making up 15 percent of its fatty acids. The fatty acids in palm kernel oil are over 50 percent MCTs with about 7 percent being Caprylic and Capric acid combined. One of the main advantages of C8 and C10 MCT Oil is that you get a high concentrated dose of MCTs that convert quickly to ketones, without having to eat big quantities of any particular food to get the same benefits.

PRODUCTION DIFFERENCES

The process in which MCT oil is produced, whether Coconut based or Palm, is called Fractionation. Other production methods include Methyl Ester Route and Winterization but, Fractionation is the method majority of producers use. There is no perfect cut of the chains during fractionation. Meaning, most products will not contain exactly 60% and 40% C10. There will always be “waste material” distributed in the 10 other MCTs (C6, C12, C14, etc.), and a catalyst or, solvent, along with water, is typically introduced during the process to facilitate the separation of chains (C8, C10). Certain solvents will yield a larger production but, those solvents can be harmful to the body like certain glycerin types and methanol.

SO WHAT’S SO GOOD ABOUT PURCHASING COCONUT-BASED MCT OIL?

It’s the sustainable and ethical buying choice.

The world is moving into a shift in buying choices of certain food ingredients to more sustainable, natural, organic health choices.

Producing Coconut oil involves the use of copra derived from coconuts which are grown on individual trees that don’t require deforestation to plant/re-plant as Asian countries such as; India, Sri Lanka, Indonesia, Vietnam, Philippines, Thailand and Malaysia are countries comprised of Coconut Palm Trees.

Palm oil’s dramatic growth has occurred for good reason. Palm oil is currently the most efficient vegetable oil crop in the world. While one hectare of land can produce just 0.38 tons per year of soybean oil, 0.48 tons of sunflower oil, and 0.67 tons of rapeseed oil, that same hectare can produce more than 3.7 tons of palm oil.

High yields and low land requirements, then, make palm oil the least expensive vegetable oil in the market. Palm oil is also versatile, as it is readily usable for baking, frying, soaps, cosmetics, and biofuel. In contrast, most other vegetable oils require hydrogenation for some food uses.

How can Coconut MCT compete with Palm MCT?

In the same game as palm kernel MCT, by price and by educating consumers.

In some countries such as the Philippines, Sri Lanka, and Indonesia, which are major coconut oil producers, steps are being taken to introduce a more competitive product into the international market. Simplifying the production process by turning to a more physical means of extracting MCTs (Methyl Ester routes, Physical processes) that don’t incorporate the use of harmful solvents. Going organic and producing an all-natural MCT Oil. More direct communication of factory-to-farmers is being more readily available for Local Coconut Farmer’s assistance which would allow lower prices of raw materials (coconuts) to be used in producing the same quality of product at a competitive price and able to provide equal and financial benefits to our Coconut Farmers.

Coconut-based MCT has dominated the primary medium-chain triglycerides source over the past few years. Palm kernel oil is also used as an important raw material source, and today it accounts for almost 34% of MCT oil production.

SO WHAT DRIVES THE BUYING DEMAND OF PALM-BASED MCT OIL?

Simply put, price. Looking back into the production of MCT oil when we start with Coconut oil and Palm oil. Coconut oil by itself has an average market price ranging between 1.00usd to 2.00usd/kg whereas average prices of Palm oil are well below 1.00usd/kg (0.20 – 0.50usd/kg).

Incorporating Palm oil as a raw material into producing MCT oil you have a final product that is cheap and typically has the same 60/40 C8:C10 respectively, as a coconut-based MCT product. Color, taste, health benefits are also the same as the benefits that you receive through C8 and C10 are universally the same.

Not only does a single coconut contain more healthy MCTs than a pound of Palm seeds. Coconuts are also known worldwide for its many health benefits and the many products that can be made such as; Coconut oils, Vinegar, Water, Milk, and Sugar. Palm fruit oils and palm kernel oil are high in saturated fatty acids (LCTs) and Industrial trans-fatty acids (TFAs), and esterified with glycerol. According to the World Health Organization, evidence is “convincing” that consumption of TFAs may also increase the risk of Alzheimer’s disease and certain cancers, and worsen insulin sensitivity, thereby increasing the risk of type 2 diabetes.

This production of Palm oil comes with a price as international awareness was created to address huge issues of deforestation, land grabs and global warming in 2004. Lack of global standard regulations allow Palm oil producers to grab a huge edible oil market share and continuously push for expansion by deforestation and un-ethical land grabs from native indigenous tribes and local wild life.

Frequently pitting plantation owners holding government concessions against native inhabitants with traditional land tenure. And if palm oil consumption continues to grow, as much as 15 million additional hectares of land, equivalent to five times the size of Belgium, will be needed by 2050.

With incorporating a versatile product such as MCT Oil into their daily routine. People have to look beyond the “basic” information and go into the chemistry of the product. As important as it is for customers to be looking at ingredients under the Nutrition Facts label of their typical grocery store products. The same has to go to understanding how a product like MCT is produced, what ingredients are involved, how it impacts them individually and globally; by purchasing this product how am I contributing to better care for our planet.

Sources:

Adrian Hernandez, Founder/CEO IRIE-Coco. Pioneer of Coconut Products and Coconut Bi-Products.

AIR AND WATER FILTRATION USING ACTIVATED COCONUT CHARCOAL

New regulations passed by the Environmental Protection Agency require coal and oil fired power plants to reduce their mercury and other toxic emissions by 2015. Current mercury technologies include the use of activated carbon injections. Most of the environmental problems of the present day including pollution are essentially man made. Water pollution is the contamination of natural water by chemical, physical, or pathogenic microbial substances making way for unsustainable life.

Reports by the Freedonia Group mention the U.S. demand for activated carbon used in industrial air and water purification applications is expected to increase to 235 million metric tons. Environment field activated carbon absorption has numerous applications in removing pollutants from air or water both in the field in industrial processes such groundwater remediation, drinking water filtration, air purification; from sources of painting, dry cleaning, gasoline dispensing operations, and other processes.

WHAT'S THE DIFFERENCE BETWEEN A HEPA AND CARBON BASED FILTER?

A HEPA (high efficiency particulate air filter) type air filter has become the most popular method of trapping the particles that get stirred up every time we walk across the floor or sit on the furniture. Most folks will use a HEPA filter as part of the exhaust on the vacuum cleaner, as the dense filtering material works to catch dust and assorted pollutants. HEPA filters are mechanical and are more efficient used in a portable systems sporting 3 to 4 filtration cycles for the HEPA filter to actually work. Microbes are trapped through randomly woven fiberglass and remain until removed or cleaned.

Carbon filters on the other hand use absorption to filter substances in the air and water. Taking in contaminants into its porous surface making it more effective when used in abundance compared to a more compact HEPA filter. When there is no more surface left to adsorb to the activated carbon, it is depleted of its capability to be effective. Large amounts of carbon will last longer than small amounts because it has larger amounts of surface area for adsorption. Also, depending on amounts of pollutants being adsorbed, a small amount of carbon can be depleted within weeks making it useless.

WHY COCONUT SHELL BASED ACTIVATED CHARCOAL IS OPTION OF CHOICE.

Typically, activated carbon is made from coal. But given the non-renewable nature of this material, manufacturers are looking for other resources of carbon, such as carbonaceous agricultural bi-products, to prepare activated carbon. Coconut shell based activated carbon are a good resource because they have a high carbon content, and a low ash content. Coconut shells are usually the waste products of coconut processing plants such those who produce coconut oils and coconut flakes. Their disposal is costly and may cause environmental problems. By using the shells to make activated carbon, the plant is not only using an abundant and renewable resource, it is also saving on raw material costs by purchasing the waste shells from coconut plants.

Coconut shell carbon's superior level of hardness makes them cleaner than most other carbons and gives them longer life expectancy. This, combined with their high activity level, makes them well suited for use in any kind of carbon filter or system. Coconut shell carbon has mainly micro-pores to meso-pores, and due to its unique distribution of pores diameter, coconut activated carbon are very popular in the gas phase purification and potable water purification industries.

Activated Carbon Coconut Charcoal, "The new soil" and the fight against CO2 emissions

The increase of popular branded media leads to consequences such as increase in soil acidity, increased fertilization costs, loss of moving parts and the threat of environmental health. In order to compensate for this, an alternative must be put in place that can influence the progression of agricultural soils. They must be able to contribute to the fixation of nutrients and make them available to plants. Activated Carbon Charcoal addresses this concern as a direct alternative. Activated Charcoal contributes to the immobilization of nitrogen and in fact, the addition of charcoal in heavily weakened tropical soils improves their physical, chemical and biological properties. As a result, these soils can acquire good cation exchange capacities (CEC) and better capacities to retain and recycle nutrients over long periods of cultivation. Activated Coconut Charcoal also influences the biological structure of the soil by its composition and abundance. It has a high ratio surface to volume and a high affinity for inorganic ions.

Its use in cropping systems contributes to the reduction of greenhouse gas emissions. The incorporation of activated coconut charcoal on the soil modifies its water state and influences the root development of plants as well as the fauna of the soil. It acts as an adsorbent complex of nutrients, and so helps the soil to fix nutrients like carbon, nitrogen, phosphorus, potassium and calcium. This work is in the context of improving farmers’ incomes by reducing the costs of inputs.

COCONUT SHELLS AND BIO-MASS

Coconut shell is an agricultural waste and is available in plentiful in many tropical countries such as the Philippines. In many countries, coconut shell is subjected to open burning which contributes significantly to CO2 and methane emissions. Coconut shell is widely used for making coconut charcoal for fueling factory expeller machines and boilers. The charcoal produced using traditional methods (pit burning, barrel burning) is of variable quality and often contaminated with extraneous matter and soil. The smoke evolved from the pit method is not only a nuisance but also a health hazard.

The coconut shell has a high calorific value of 20.8MJ/kg and can be used to produce steam, energy-rich gases, bio-oil, biochar etc. It is to be noted that coconut shell and coconut husk are solid fuels and have the peculiarities and problems inherent in this kind of fuel. Coconut shell is more suitable for pyrolysis process as it contain lower ash content, high volatile matter content and available at a cheap cost. The higher fixed carbon content leads to the production to a high-quality solid residue which can be used as activated carbon in wastewater treatment. Coconut shell can be easily collected in places where coconut meat is traditionally used in food processing.